- Cost savings up to 35 percent compared to standard wet painting

- Integrated coloring process combines direct fabrication and surface coloring

- Scratch-resistant surfaces, novel design options and lower production times

NASHOTAH, Wis.–(BUSINESS WIRE)–Techniplas, a leading global design and manufacturing provider of automotive products and services, announced today the launch of ColorFuse, an integrated manufacturing process of injection molding and painting for direct fabrication and surface coloring that can quickly produce high gloss and scratch-resistant parts, and multi-textured exteriors with novel design options, which has already received requests for quotes from a variety of car manufacturers worldwide, with two production lines running in Europe today.

To view the media kit, please click here.

Material cost savings with ColorFuse can be as high as 35 percent compared to standard wet painting processes while still achieving the same high gloss piano black appearance in an A-Pillar application and fulfilling the scratch resistance criteria.

ColorFuse can be integrated into existing manufacturing processes without investment in complex painting lines. Compared to conventional processes, colors can be changed in much less time as the paint coating is applied directly to the part in the closed mold, removing an entire step from the production process to decrease production times.

Independent of the carrier material, a molded part is flow-coated with a polyurea reactive lacquer while still in the multi-component tool and then leaves the mold in the desired color with no extension to the injection molding cycle.

“ColorFuse changes the game for coloring interior and exterior car parts,” said Daniel Spirig, President of Techniplas Prime and ColorFuse. “Manufacturers gain a one-step process of injection molding and painting combined for direct surface coating with no post mold processing. By combining these processes, parts can be manufactured faster at lower cost with innovative design options including elegant surface aesthetics and logo depictions.”

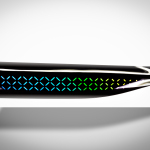

Unlike genuine metal surfaces, ColorFuse metal effect surfaces are largely scratch resistant and resilient against climatic and environmental effects such as UV radiation. Manufacturers can choose from a variety of colors, varying surface textures, clear coat surfaces with depth effects, partial textures, designer lines, and lettering.

Enabling precise accents and styling lines, ColorFuse offers high gloss, matte or grained surfaces for car interiors and exteriors. Currently being used worldwide, ColorFuse’s material properties are less environmentally damaging compared to commonly used lacquer systems, offering an ecologically-friendly solution.

A full service supplier offering design, prototyping and testing of automotive parts, Techniplas’s product management and testing and validation center offers an ideal platform for pre-trials or development projects for auto manufacturers. As part of Techniplas’s expansion of its R&D and production capabilities in Treuen, Germany, the company launched a second serial production line and opened a new Testing & Validation Center ColorFuse line to focus on the development of decorative surfaces.

“ColorFuse not only provides best in class surfaces at very competitive prices, we also combine it with our wider Techniplas technologies and offerings to deliver a complete range of production capabilities,” said Spirig.

About Techniplas

Techniplas is a leading global design and manufacturing provider of engineered products and services that are helping to shape the future of mobility. Our 2,000 associates around the world are passionate about making the connected world. By continuously expanding the reach of our data-enabled cognitive technologies into everything we do, we deliver personalized, performance-enhanced and sustainable mobility. Learn more at www.techniplas.com.

Contacts

Alyssa Hoyt

Alyssa@xponentialworks.com

+1-310-691-0788