In the ever-evolving landscape of the automotive industry, the role of the autobody technician has metamorphosed far beyond the traditional confines of wrenches and paint. Today’s modern autobody professionals are not just mechanics; they are technologically savvy artisans and critical thinkers, confronting an array of challenges and innovations in their daily work. Here, we delve deep into the chronicles of these unsung heroes, exploring the realities behind the wrench in the modern collision repair world.

The Modern Toolkit

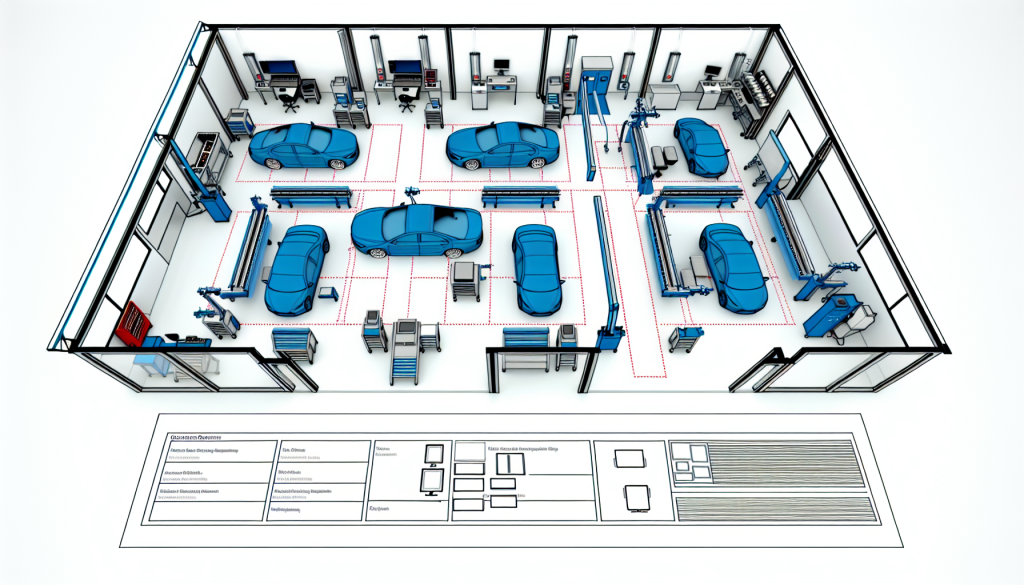

Gone are the days when an autobody technician’s toolkit was limited to hammers, sanders, and spray guns. Today’s toolkit has expanded to include sophisticated diagnostic software, 3D scanners, and advanced welding equipment that can handle the variety of materials now used in vehicle construction, such as high-strength steel, aluminum, and carbon fiber. Technicians must continuously update their knowledge and skills to keep pace with these technological advancements, making education and adaptation their constant companions.

The Digital Evolution

The collision repair process has also been transformed by digital technology. From computerized color matching systems for paint jobs to the use of augmented reality (AR) for damage assessment and repair planning, technology is reshaping the way autobody technicians work. This digital evolution requires technicians to be not only adept at using these technologies but also capable of interpreting the data they provide to make precise and efficient repairs.

The Importance of Continuous Learning

With vehicle manufacturers introducing new models at an increasingly rapid pace, each with its own set of unique repair procedures and materials, the importance of continuous learning cannot be overstated. Modern autobody technicians often spend a significant portion of their careers in training seminars, certification courses, and online learning modules to stay current with industry standards and trends. This commitment to education is paramount to ensuring the safety and reliability of repair work.

Embracing Sustainability

Sustainability has also become a priority in the collision repair industry, with a growing emphasis on eco-friendly practices. This includes the use of water-based paints, recycling of materials, and the adherence to stricter environmental regulations. Autobody technicians are at the forefront of implementing these practices, often innovating new ways to reduce waste and decrease the environmental impact of their work.

The Challenge of ADAS

Advanced driver assistance systems (ADAS) present one of the most significant challenges in modern autobody repair. These systems, which include features like adaptive cruise control, collision detection, and lane-keeping assistance, require precise calibration after many types of repairs. Technicians must have a detailed understanding of these systems to ensure that they are functioning correctly post-repair, adding another layer of complexity to their role.

The Art of Restoration

Despite the technological and procedural advancements, the heart of autobody repair remains in its artistry. Modern autobody technicians must have a keen eye for detail and a steady hand to restore vehicles to their pre-collision condition. Whether it’s perfectly matching the paint color or ensuring that body lines and gaps are uniform, the quality of a technician’s work is evident in the seamless appearance of the finished vehicle.

The modern autobody technician is a hybrid of mechanic, engineer, artist, and computer technician, equipped with a diverse skill set to meet the demands of today’s automotive repair challenges. Behind the wrench, these professionals navigate a complex world of innovation and change, driven by their commitment to safety, quality, and craftsmanship. Their work is not just about repairing vehicles; it’s about restoring peace of mind to those affected by collisions, one car at a time.