EXPLORING THE ECCENTRICITIES OF MODERN AUTOMOTIVE TECHNOLOGY

BY SARAH PERKINS

With technological advancements increasingly seeming to defy the limits of the imagination, the automotive industry frequently stands at the forefront of innovation. Just as frequently, however, OEMs offer an array of peculiar technology that blurs the lines between science fiction and reality. From vehicles that turn the driving experience into a musical to electric vehicles that resist drag, read below to see the sometimes wonderful, sometimes wacky innovations that manufacturers hope will make it into future vehicles (and more importantly, hope that repairers will be able to fix).

CRUISING IN HARMONY

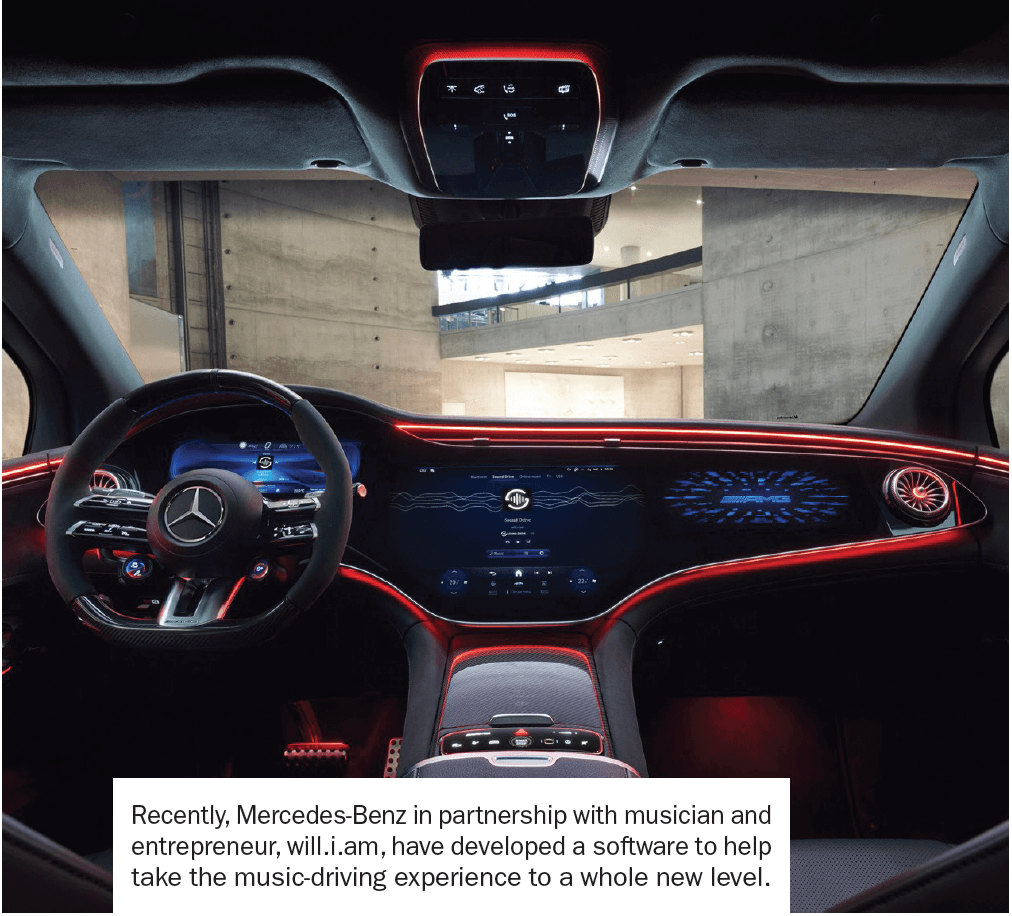

Recently, Mercedes-Benz in partnership with musician and entrepreneur, will.i.am, have developed a software to help take the music-driving experience to a whole new level.

Showcased at the 2024 Consumer Electronics Show (CES) in Las Vegas, Nevada, the MBUX Sound Drive aims to put drivers into the conductor’s seat by using the movements and inputs of the vehicle to augment the way a song is played inside the car’s cabin. Specifically, MBUX Sound Drive works by using the sensors found on any vehicle—the accelerator, accelerometer, gyros, suspension, steering wheel and brake—and turns those inputs, as they occur in real time, into ways to compose, rearrange and create music being played through the vehicle’s sound system. When the accelerator is pushed down, that turns up the bass line in the music playing; turning the steering wheel will make the synthesizers come to life; and pressing down on the brake pedal will cause the reverb to plug in.

Like a DJ spinning a new track, drivers using the MBUX Sound Drive system can create remixed versions of songs just by spinning the steering wheel in place of a turntable.

ACTIVATING AIR

Another example of novel technology that hopes to someday make its way to the production stage is Hyundai Motor Company and Kia Corporation’s patent application for an Active Air Skirt technology—a system designed to improve electric vehicle range and stability by reducing aerodynamic drag at higher speeds.

According to the patent, the Active Air Skirt is installed between the front bumper and front wheels and is not visible during normal operations. The technology functions by directing the flow of air entering a vehicle through the lower part of the front bumper.

At speeds above 80 km per hour—when aerodynamic resistance becomes greater than air resistance—the system would engage and disengage again when the vehicle drops below 70 km per hour. The technology can also operate at speeds above 200 km per hour. Hyundai says this is possible because of the use of rubber material on the lower section of vehicles which improves durability and reduces the risk of external objects damaging parts at higher speeds. Hyundai has tested this technology in the Genesis GV60 and found it reduces the drag coefficient (Cd) in the vehicle by 0.008 (Cd), a 2.8 percent improvement or roughly six extra kilometres added at a full charge.

The technology also works to increase the downforce on the vehicle which improves traction, reduces wind noise and increases stability at higher speeds.

While the Active Air Skirt is still at a patent stage, once it goes through additional durability and performance testing, Hyundai plans to consider it for mass production.