ROBOTIC REFINISHING PROCESSES, RADAR-SAFE REPAIRS AND MORE AT AKZONOBEL OPEN HOUSE

BY ALLISON ROGERS

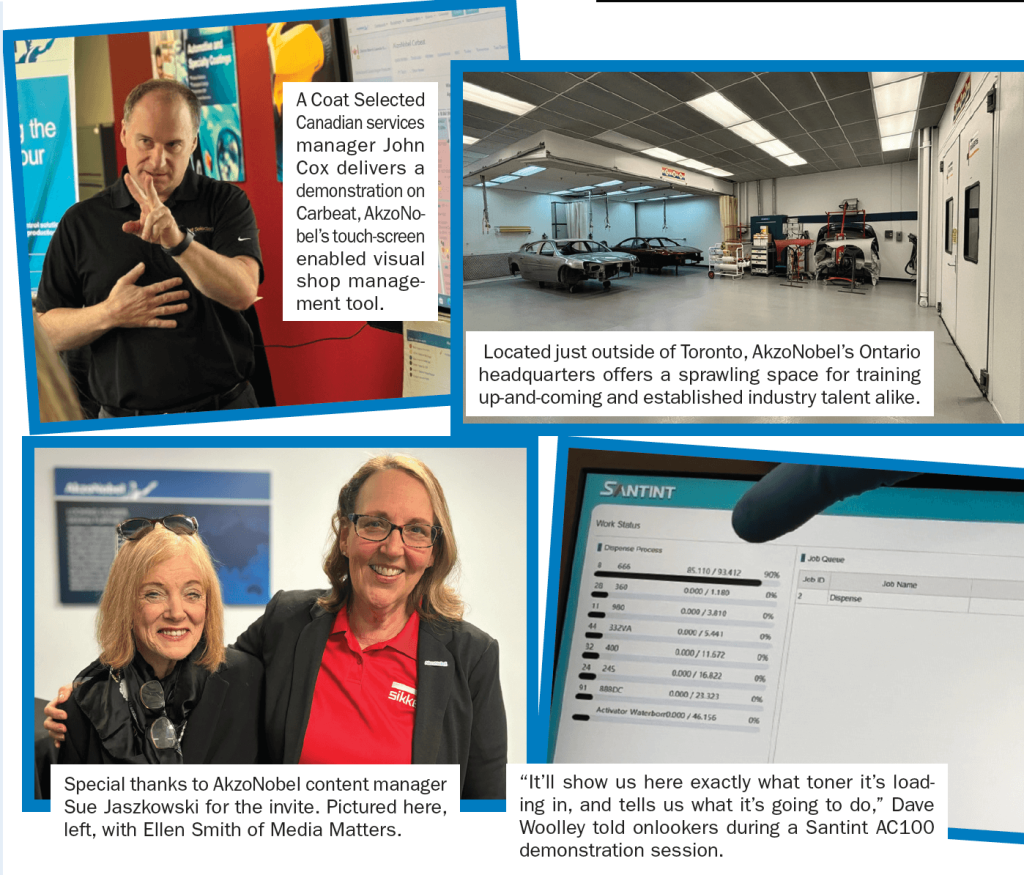

Dozens of Canadian industry reps were at the AkzoNobel Ontario headquarters and training facility in early February as the coatings company hosted an Open House for its valued partners and customers.

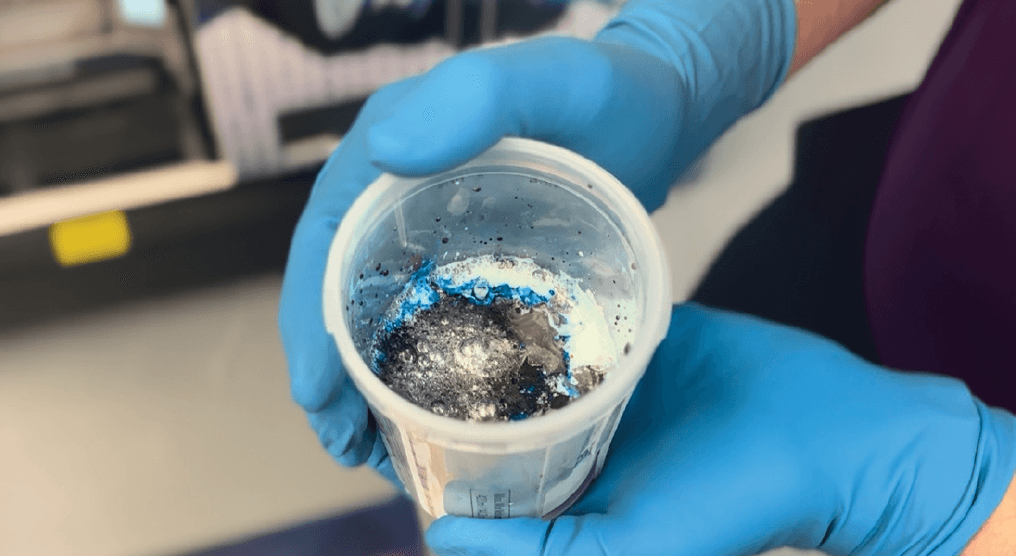

The main feature of the day was AkzoNobel’s brand-new AC100 automated paint dispensing machine, created with Santint, which, according to AkzoNobel technical trainer Dave Woolley, allows anyone in the bodyshop to mix a perfect cup of paint.

“Painters, of course, but customer service reps, technicians, apprentices—anyone, really. And it takes about five minutes.” “It saves a ton of time for the painter. And, if you can get one more cycle in per day because of this tool, then that’s money on the table.”

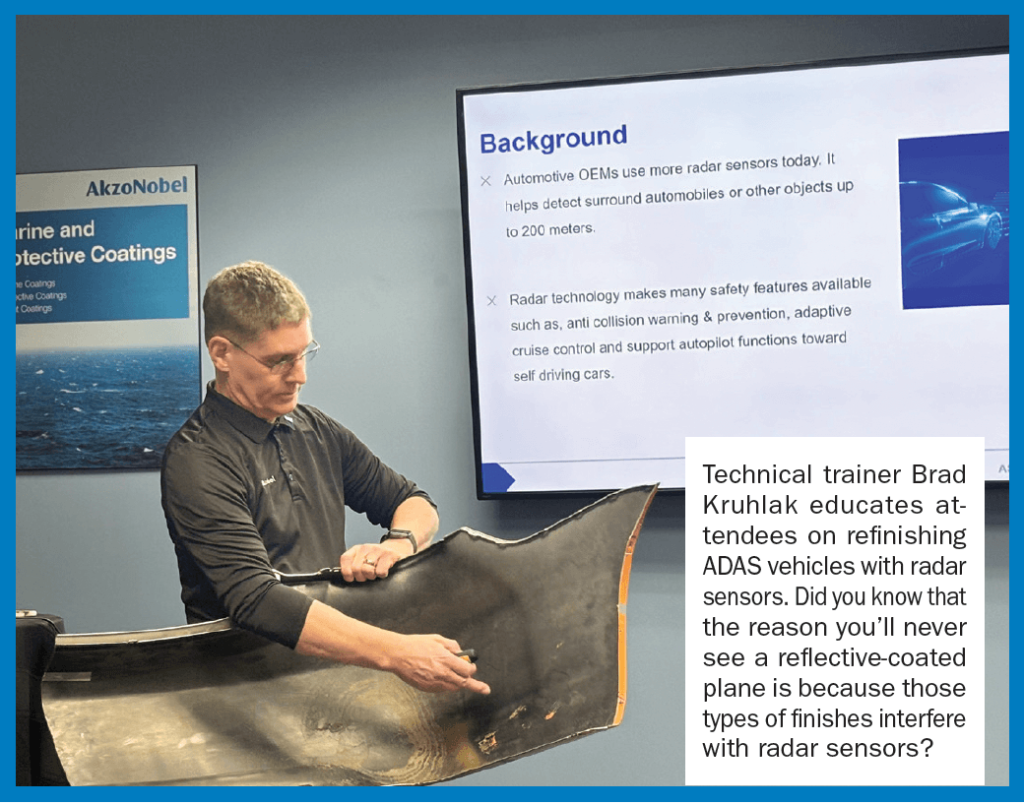

Attendees, which included shop representatives, insurance partners, OEM reps, networks and more, were also given the option to sit in on a training session led by Brad Kruhlak, technical trainer, who delved into the specifics of refinishing radar-enabled cars.

One interesting fact noted by Kruhlak was that Mercedes-Benz has recently taken up the strategy of housing its radar sensors in non-painted parts, saving the technician quite the headache when deciphering what can and cannot be painted during a repair.

One of the most intriguing parts of the day was a room dedicated to brainstorming potential solutions to the skills shortage. AkzoNobel posed questions like, “When should the industry begin engaging with youth?” and “What is not working when it comes to engaging our youth?” and attendees were invited to write their thoughts on the board.

REFINISHING RADAR » FAST FACTS

• Automotive OEMs use more radar sensors today, moving from 22 GHz to 77 GHz. Radars are used to help detect surroundings, other automobiles and other objects up to 200 metres away.

• Repair methods can differ from OEM to OEM; even within an OEM, different models can have different procedures.

• The use of primer and body filler is, in general terms, not allowed in the radar at zone. Welding and the use of repair staples is most definitely not allowed within repair methods issued by OEMs.

• Dependent on the colour and other factors, some OEMs will give guidelines dictating what is possible to refinish up to three times. This is only possible when the existing OEM finish has not been damaged or sanded through preparation. Only approved colours can be refinished.

• On most OEMs, there is strict guidance on the layer thickness for each refinish material applied. This includes adhesion primers, primer filler, base coat and clear coat.