NEVER WONDER WHICH PRIMER YOU SHOULD USE AGAIN

BY JUSTIN JIMMO

Primers are an unavoidable aspect of working in the collision repair industry, so it’s vital to know how to use them well. The most basic function of a primer is to protect and ensure proper bond to the surface you will be applying paint to, and the primer that will best perform this task depends on many different factors. Educating yourself on what primer is best suited to your specific needs can go a long way in increasing workflow and improving shop profitability. Using the wrong primer in the wrong way can result in lower quality final products, due to adhesive issues. There are several different primers you will come across in the collision repair industry. In this “how to” series, we will take a look some of the most common primers, when they should be used, and how.

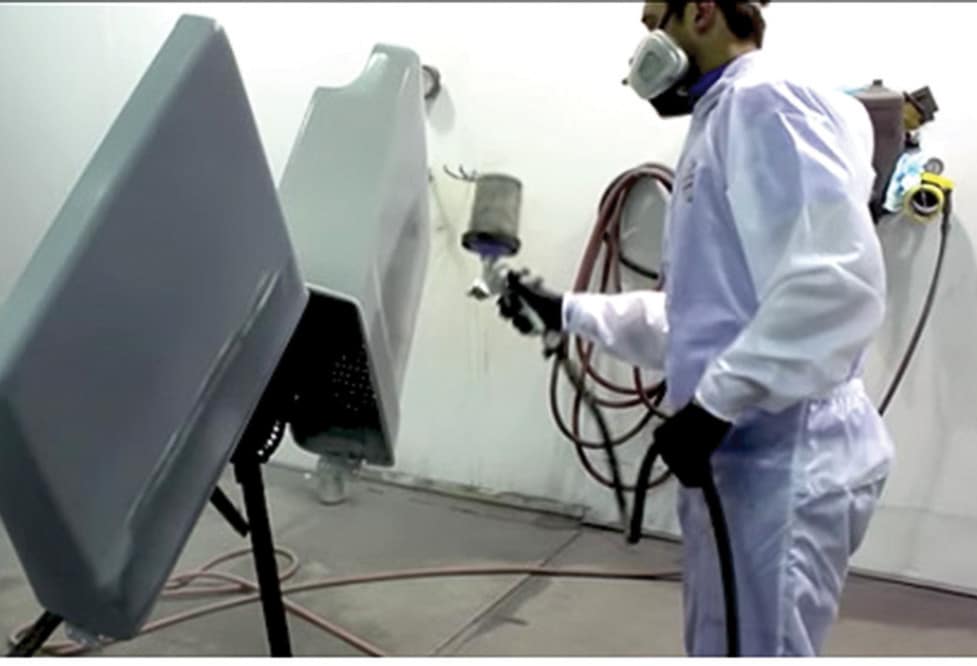

Primer Surfacer

A primer surfacer is used to provide some filling during a repair. It may be applied over body fillers, or used to rebuild any area of paint where levelling is required. To properly use a primer surfacer, it will require sanding after its application, before layering on a coat of paint. Generally, this breed of primer is urethane based, and can in some instances be Used to provide some filling during a repair, primer surfacers can be applied over body applied directly to metal or plastic.

Non-Sanding Primer/Sealer

This primer is similar to a primer surfacer, but does not need to be sanded and is applied at the time of painting. Non-sanding primer/sealer does provide some filling, and commonly, this primer is coated on top of new OEM parts or over repairs to provide better holdout.

E-Coat

E-coat is a factory coating found on new panels. It is applied by dipping electrically charged parts into a paint vat. E-coat is extremely thin, which means paint cannot be applied directly over it. Instead, non-sanding primer or primer surface must be used in conjunction with the E-coat, and applied on top of it.

Epoxy Primer

A durable primer that can be used in a variety of ways, including beneath a urethane primer to provide additional corrosion protection, as a primer surface, or as a non-sanding primer. This primer will take longer to dry than a urethane based primer, but has many handy features that make up for this. It can be applied directly to metal, has good sanding characteristics and provides superior holdout.

Etch Primer

This primer is an acidic-based coating designed to be applied on bare metal. It contains no filling properties, and is specifically designed to prepare bare metal to be coated with another primer or paint product.

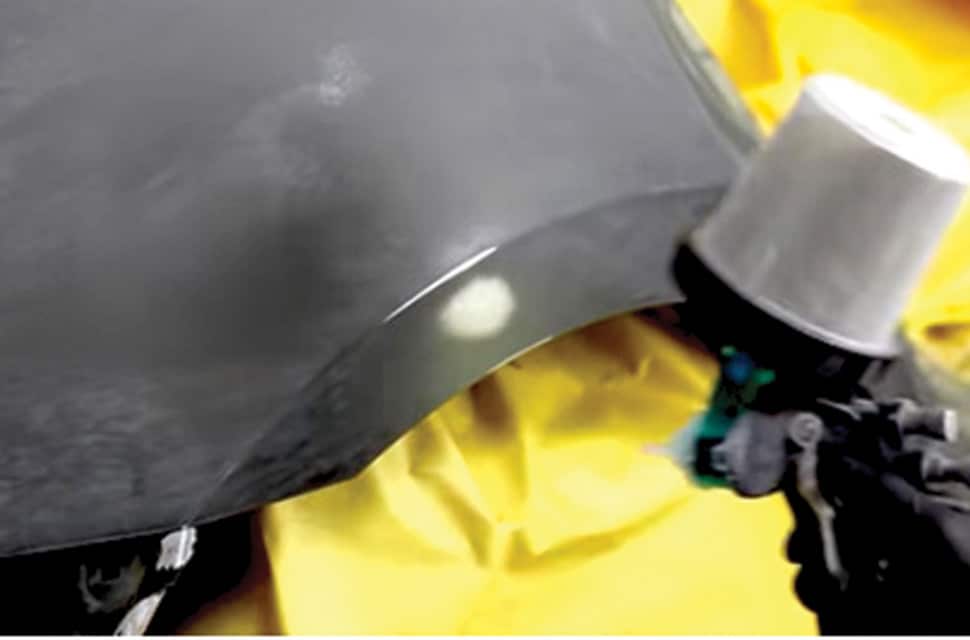

Plastic Primer/ Adhesion Promoter

This primer is an acidic-based coating designed to be applied on bare metal. It contains no filling properties, and is specifically designed to prepare bare metal to be coated with another primer or paint product.

UV Primer

With the recent advancements in UV lamp technology, UV curing primer is becoming a more popular choice in high production shops. UV primer is a very high building product that can be completely cured and ready to sand in seconds. Activated by exposing the coating to a UV light source, this primer will be more transparent in order to allow for light to penetrate though it.

Extras

You may also encounter additional specialty primers, such as waterborne or polyester primers. In some cases, these primers can be a great solution.

Avoid

You generally want to avoid one-part aerosol primers that claim to provide filling characteristics. Primers of this sort lack the required strength to do the job well. If using one-part aerosol primers, you may also encounter compatibility issues with the paint applied over it.