THE MAJOR DIFFERENCES BETWEEN EVS AND ICE VEHICLES, AS IT RELATES TO COLLISION REPAIR

BY MICHAEL VAVAROUTSOS

Electric vehicles (EVs) are beginning to dominate the streets around us. As more and more people continue to make the switch from internal combustion engine (ICE) vehicles to fully electric and hybrid vehicles, collision repair shops should start thinking about the differences between repairing an ICE vehicle and an EV.

When it comes to collision repairs, there are some major differences and tools required for EVs compared to ICE vehicles. For starters, EVs have a high voltage battery and voltage wiring throughout the whole unit. This can make it extremely dangerous for technicians without proper training, as they have to have the ability to remove and replace the high voltage components, including the battery. David Mayers, CEO of Environmental Motorworks, stresses the importance of taking the proper precautions when repairing an EV. “EVs have a high voltage battery, and they have voltage wiring throughout the unit, they can be in the weirdest spots. When it comes to collision repair, it can be quite dangerous,” Mayers explained.

“You don’t have that in an ICE vehicle, you never have to worry about a wire that’s hanging down. But you really must power down these EVs in order to work on them safely.” Mayers emphasized that the cables and wires in the body of the vehicle can pose threats and need to be addressed. He says that EMW has done small training courses to help show the dangers of working with these high voltage vehicles.

“In one situation at our training course, we had an example where we show that even the smallest of wiring—maybe around 18-gauge—carries some pretty high voltage.” While there is the electrical aspect for EVs that ICE vehicles don’t have, there are also certain components of the vehicle that can be different. Mayers says that in recent years, body parts for EVs are much different than ICE vehicles. Although, this wasn’t the case when EVs fi rst became available to customers. “Going back to the first generations of EVs, they were not really built as electric vehicles, they were ICE vehicles that have been adapted. So, at that time, many of the body parts and things like that were very much the same,” he said.

“But in the next generations, you’re seeing that they are different. Now there are different components, different areas that need to be changed or adapted.”

David Giles, EV education product specialist for ConsuLab and president of PoweredEV, says that manufacturers are continuously experimenting with different materials and processes for EVs.

While the materials in EVs are similar to ones in modern ICE vehicles, the way they are used can be quite different.

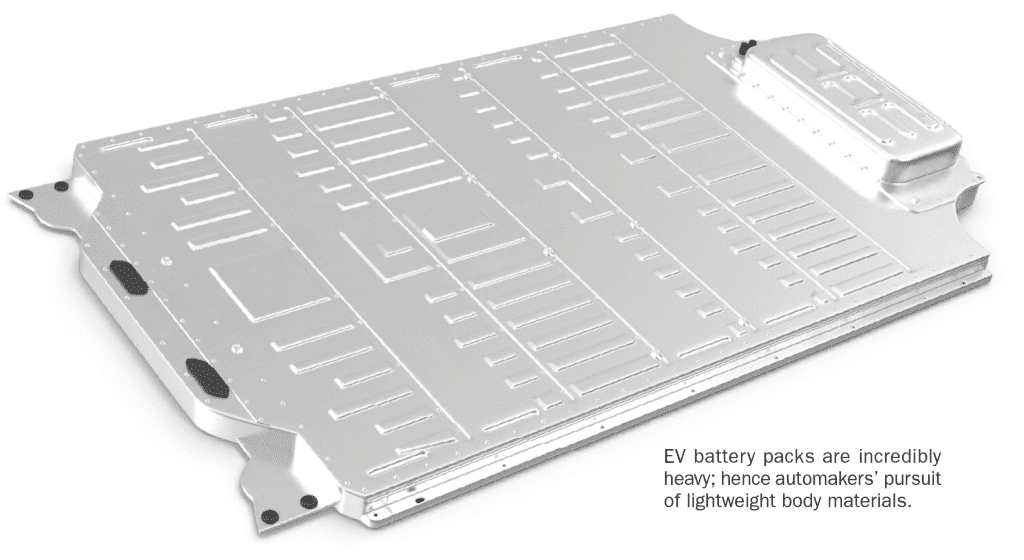

“Aluminium forming is a big thing. So rather than having separate sections bolted together, they’re all in one piece,” Giles said. “Where we conventionally would have rails, rear frame rails and so on that could be cars don’t have that capability. “So that means in a severe rear end collision, it’s more likely the car will be a total loss in comparison to ICE vehicles.”

came into popularity. The fact of the matter is that EVs can sometimes take longer to repair, due to the electrical components mounted and placed in different areas within the engine bay and elsewhere inside the vehicle.

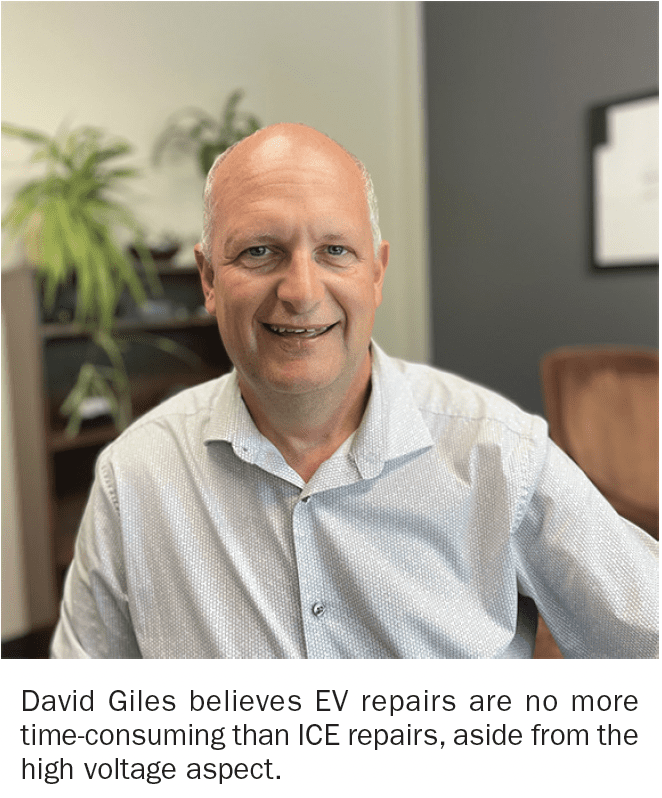

“I don’t think [repairs] take longer on EVs, but there’s an inherent respect for the vehicles, knowing there’s high voltage there. At the end of the day, the vehicles themselves run the same, but having to remove the high voltage components can be a little more time consuming,” Giles said.

As EVs continue to increase in popularity, bodyshops should take the time to understand the differences of how to repair these types of vehicles. Since these vehicles are still relatively attached and removed, some of these newer The question of if EVs take longer to repair than ICE vehicles has been raised since EVs new to the market, it is important to take on as much specialized training as possible to ensure that technicians are EV-ready. “Collision centres need to look at their own capacity, technician skill level, tooling requirements, charging infrastructure, model mix of vehicles, partnership with local dealers and insurance relations, as well as to stay on top of industry trends, to ensure it makes business sense for them to offer and provide EV repairs,” said Paul Stella, manager of collision repair and refinish at Toyota Canada. This not only involves the understanding of different components in an EV, but also being trained in safety precautions, proper repair procedures and handling, repairing and replacing the high voltage batteries. “Again, it’s extremely important for any collision repair centre to follow all manufacturer instructions and guidelines, especially the repair manual, to ensure proper steps are followed,” Stella added.