VIRTUAL REALITY HOLDS IMMENSE, IMMERSIVE POWER —JUST ASK ATA’S COLLISION OLYMPICS COMPETITORS

BY ALLISON ROGERS

PHOTOS BY DORIS KADORF PHOTOGRAPHY

Let’s face it—it can feel impossible to find joy in some jobs. It’s not impossible, but it sure can feel like it. When you’re working long hours with little reward; cursing your coworkers and feeling like life’s at a dead-end…what a dreary image. Many of us in the collision industry have no idea what that is like.

Constantly advancing technologies are the key to keeping the industry engaged, according to many of the sector’s top training providers, business consultants—even those in the industry themselves credit technologies and the idea of a car as a “computer on wheels” as a key point to highlight when attracting new talent to the trade.

Yet, one technological trend has emerged in recent years—and it’s taken the entire industry by storm. We’re talking about virtual reality (VR) training. You know, when you don that silly headset and wave your hands around like a lost octopus?

The Automotive Trades Association of Manitoba (ATA of Manitoba) recently hosted its Collision Olympics, where shops from the area went head-to-head in a contest of skill and precision.

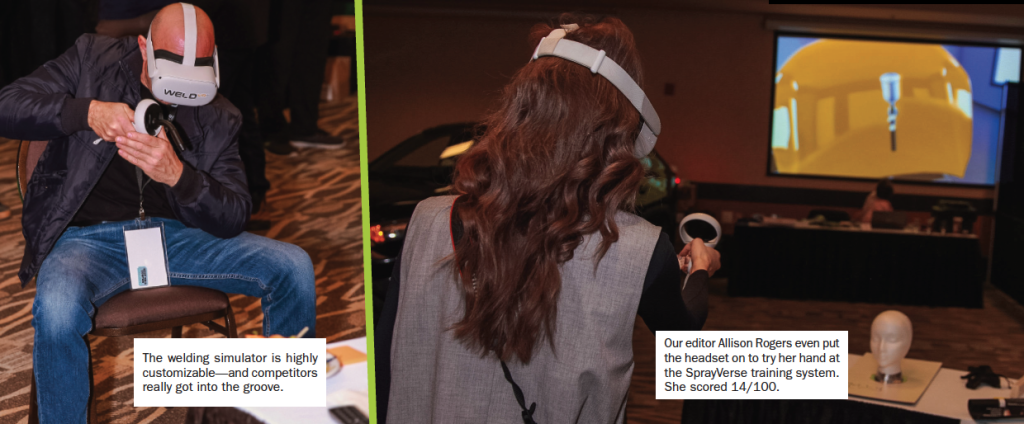

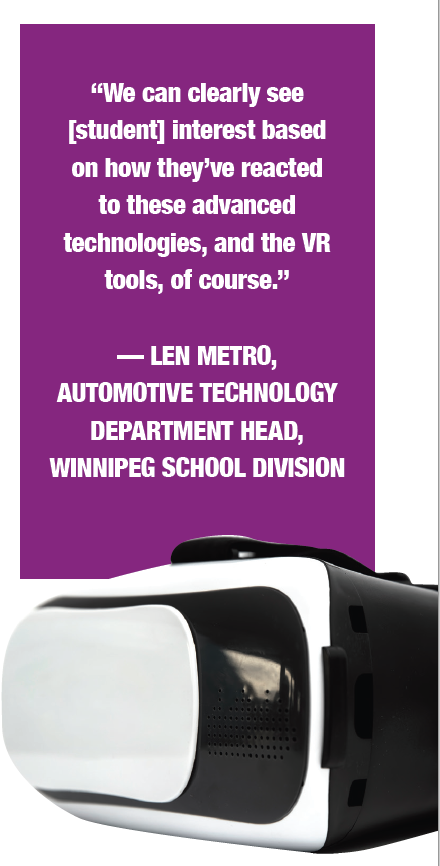

Separated into two segments—the morning saw autobody students compete while the evening brought the pros to the stage—ATA’s Collision Olympics also offered some pretty stellar prizes to the group. The first-place student winners in the paint and welding categories each walked away with a brand-new PlayStation 5, while the professional-level victors took $7,000, $2,000 and $1,000 back to the bodyshop for their valiant efforts. Students competed for the best scores in two skill categories—refinishing and welding. Competitors donned an Oculus headset outfitted with Cythero’s VR training technology, the SprayVerse for painting and Weld VR for welding. More than 150 students visited the ATA of Manitoba’s Trade Show, and dozens of them wielded the Oculus for a chance to try their hand at refinishing and automotive welding. “[These students] are an incredibly engaged group,” said X, one of the crew’s teachers and trip supervisors. “I know at least a handful of them have shown interest and skill in the automotive trade. It’s refreshing to see such a committed and excited bunch right here in Winnipeg—we can clearly see their interest based on how they’ve reacted to these advanced technologies…and the VR tools, of course.” “It was super cool. It felt like I was back in shop class,” one student told Bodyworx Professional.

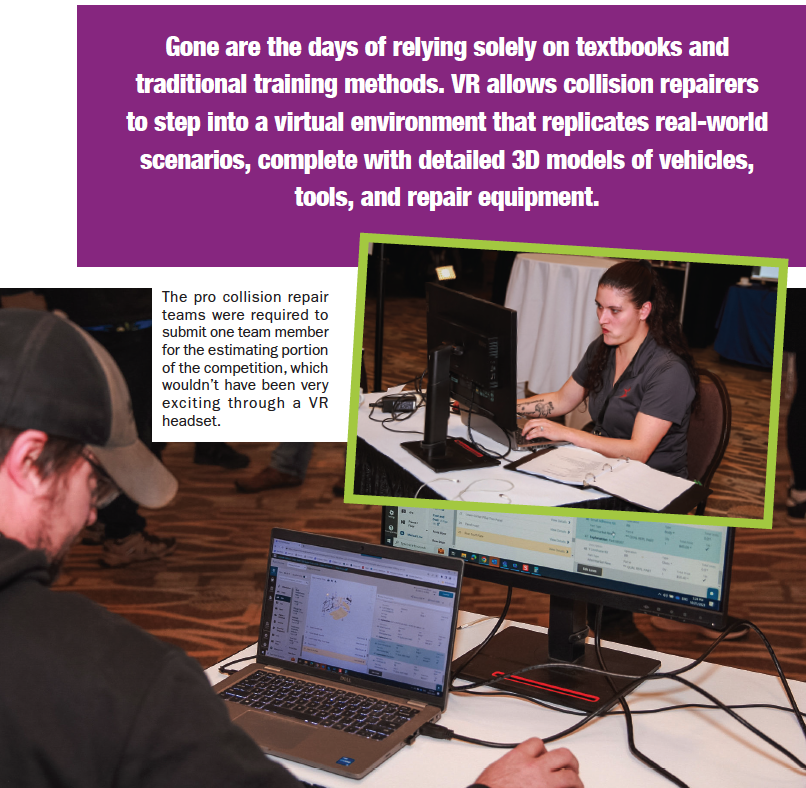

The “big kids”—i.e., the pros—had a greater challenge. Shops formed teams of three—one competitor handled the paint portion; another, the welding bit; and the third performed a mock estimate. Points were added up to determine the best overall team. Eastside Collision Repairs Ltd. came out on top and took home the $7,000 grand prize.

In the ever-evolving world of collision repair, VR technologies are revolutionizing the way collision repairers are trained. With the integration of VR into training programs, collision repairers can now undergo immersive and realistic simulations that enhance their skills and expertise.

The allure of cutting-edge technology and immersive experiences can captivate and engage potential trainees, drawing them into the field of collision repair. Once there, these novel tools have the power to draw talent from even deeper—teach muscle memory movements, terminology, et cetera—and shape a skilled collision repairer or refinisher.

Gone are the days of relying solely on textbooks and traditional training methods. VR allows collision repairers to step into a virtual environment that replicates real-world scenarios, complete with detailed 3D models of vehicles, tools, and repair equipment. Through VR headsets and motion controllers, repairers can practice painting skills of various intricacies (and on dozens of different parts); lay a weld bead; disassemble and reassemble parts—and even perform intricate repairs, all within a safe and controlled virtual space.

The benefits of VR training for collision repairers are manifold. Firstly, trainees can gain hands-on experience without the risk of damaging actual vehicles or equipment—an obvious cost-saver. They can practice various repair techniques repeatedly until they achieve mastery, building muscle memory and honing their skills in a risk-free environment.

Moreover, VR training offers a level of interactivity and engagement that traditional methods can’t match. Repairers can collaborate with virtual instructors or colleagues, exchanging insights and receiving real-time feedback on their performance. This fosters a dynamic learning environment, encouraging problem-solving, critical thinking, and effective communication—all vital skills in the fast-paced collision repair industry. There are even VR simulations out there that can replicate challenging scenarios that are difficult to recreate in real life, such as complex structural repairs or working on rare or exotic vehicles. By exposing repairers to these scenarios virtually, they can develop the confidence and expertise needed to handle any situation they may encounter in their professional careers. Plus, the fancy robot-looking headset just looks cool.

Beyond individual training, VR technologies also enable remote and distributed learning. Collision repairers from different locations can connect in a shared virtual space, attending virtual classes and workshops conducted by industry experts. This opens up opportunities for networking, knowledge sharing, and continuous professional development, fostering a sense of community among repairers.

It was clear from ATA of Manitoba’s competition that VR technologies are exciting for not only prospective automotive talent but longtime repairers and refinishers, too. The training technologies offer various levels and are fit to challenge even the most talented of painters and welding professionals. ATA of Manitoba is not the only organization to hop on the VR training trend. The British Columbia Institute of Technology (BCIT) has employed VR training technologies in automotive applications; as has Centennial College in Toronto and dozens of other vocational schools (secondary and otherwise) across the U.S. and Canada. 3M even uses the technology in its new American training centre. And, if you’ve walked any trade show floor in the past 12 months, you’ve witnessed someone wearing the wacky headset, probably practicing their skills.

The truth is, you will never understand the true capabilities of these VR training technologies until you wield one yourself. No one in the industry is suggesting that someone could be entirely trained as a refinisher or welder based on VR tech—you can’t spend four levels with a gaming controller in your hand and expect to lay down a perfect bead. It’s just not realistic.

The point that the ATA of Manitoba and so many others in our industry have gotten behind is that these technologies have the power to train and retain. You can use VR to up your skills, straight from the comfort of your bedroom, and regardless of your skill level. It’s time to don your robot headset and embrace these high-tech times we’re in.