IN THE SPIRIT OF HAVING A LITTLE FUN, HERE’S OUR TAKE ON THE AUTOSHOW’S MOST BUZZWORTHY VEHICLE. WHAT HAPPENS WHEN A FULL-SIZED LEGO MCLAREN GETS INTO A FENDER BENDER? HOW WOULD INSURANCE ADJUSTERS REACT???

BY WILLIAM SIMMONS

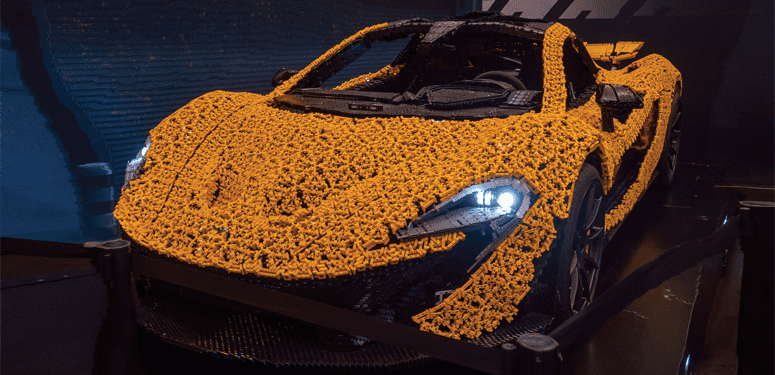

I walked into the recent AutoShow expecting to see cutting-edge technology, wild concepts, and the future of collision repair challenges. I just didn’t think the biggest question would be: How do you write an estimate for a fender bender on a life-size LEGO McLaren P1? Now, I’m used to looking at cars and thinking, How much of a nightmare would this be to repair? But this? This was a whole new level.

First of all, it’s made of 342,817 LEGO Technic pieces. Which means, if it ever gets into a collision, do we need to follow OEM repair procedures? Do we need a LEGO-certified structural technician to piece it back together? Will the repair estimate be in dollars or in minifigure currency?

And what happens if a few bricks go missing? I’ve seen insurance write off entire vehicles for a misaligned ADAS sensor—what happens when we can’t find a crucial 2×4 Technic connector that rolled under the workbench?

Speaking of insurance… good luck getting this one covered. Can you imagine submitting a claim?

Adjuster: “What was the point of impact?”

Me: “Somewhere between the rear diffuser and the childhood nostalgia.”

Adjuster: “And what’s the repair plan?”

Me: “About six weeks of swearing and a YouTube tutorial.”

Let’s not forget the real-world logistics. Is there a certified LEGO scanning system on the market? Do you calibrate the build alignment using a spirit level and your kid’s floor mat? What’s the proper torque spec for a friction pin? Is this a structural repair or cosmetic? Do we need pre- and post-scans?

Also, how do we handle parts procurement delays? Does Bricklink have a hotline for backordered Technic beams? If the build is 1,220 kg, does that make it a light truck by Canadian estimating standards? Do we charge frame time on this?

And let’s talk about repair time. If a shop follows OEM procedures to the letter, will the technicians have to sort every piece by size and colour first, like a kid dumping out a LEGO box before starting a build? What’s the labour rate for brick reassembly? Because if it’s anything like a real McLaren, I’m guessing it’s a five-digit number per hour. Heaven help the shop if they don’t document each piece reinstalled with time stamps and high-res photos. You think photo documentation is tough with bumper covers—try doing it with hundreds of 1×1 round tiles.

Then there’s quality control. Do we need a post-repair LEGO jig measurement? If it clicks, it fits, right? Or do we need a second opinion from a certified master builder with a clipboard and a magnifying glass? But the biggest question of all—if we don’t follow McLaren’s official repair guidelines and just slap it back together with super glue… will that void the warranty?

One thing’s for sure: if this thing ever ends up in a DRP shop, I’m betting the insurer will total it faster than you can say “we don’t pay for plastic welding.”

In all seriousness, this sparks genuine curiosity about the nature of materials, documentation, and what “safe repairs” look like when they’re built brick by brick.

And who knows—maybe next year, we’ll see a hot glue recalibration station or a LEGO teardown allowance on an actual estimate. I’m not saying it’s likely. I’m just saying: don’t rule anything out in this industry.