SASKATCHEWAN POLYTECHNIC’S AUTOBODY STUDENTS BREATHE NEW LIFE INTO A 1959 IMPAL A CONVERTIBLE

BY SARAH PERKINS

For students pursuing careers in autobody repair, gaining diverse hands-on experience is essential. Engaging with a wide array of materials, techniques and vehicle types— both old and new—not only builds technical skills, but also instills the confidence needed to tackle real world challenges.

In October, Scott Kucharyshen, Saskatchewan Polytechnic Auto Body program head and instructor, announced the success of this year’s Auto Body Technician students as they refined their skills refinishing a 1959 Impala convertible from being “altered almost beyond recognition,” to better than new.

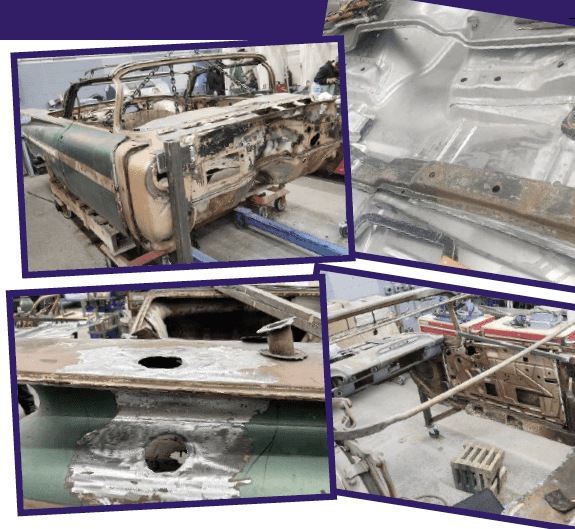

When speaking with Bodyworx Professional magazine, Kucharyshen commented that “at Saskatchewan Polytechnic, each cohort of autobody certificate students undertakes a unique restoration project. This year’s cohort tackled a 1959 Impala Convertible that had endured significant abuse over its lifetime. The car was left outside to face Saskatchewan’s harsh weather, used as a pace car with flagpole holes cut into the quarter panels. A Buick Nailhead engine and a three-speed standard transmission were haphazardly welded in, and the lower 15 centimetres of the car had nearly disintegrated due to time, abuse and salt exposure.”

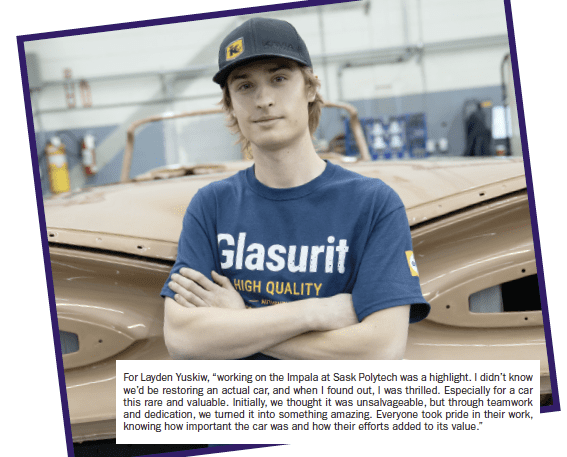

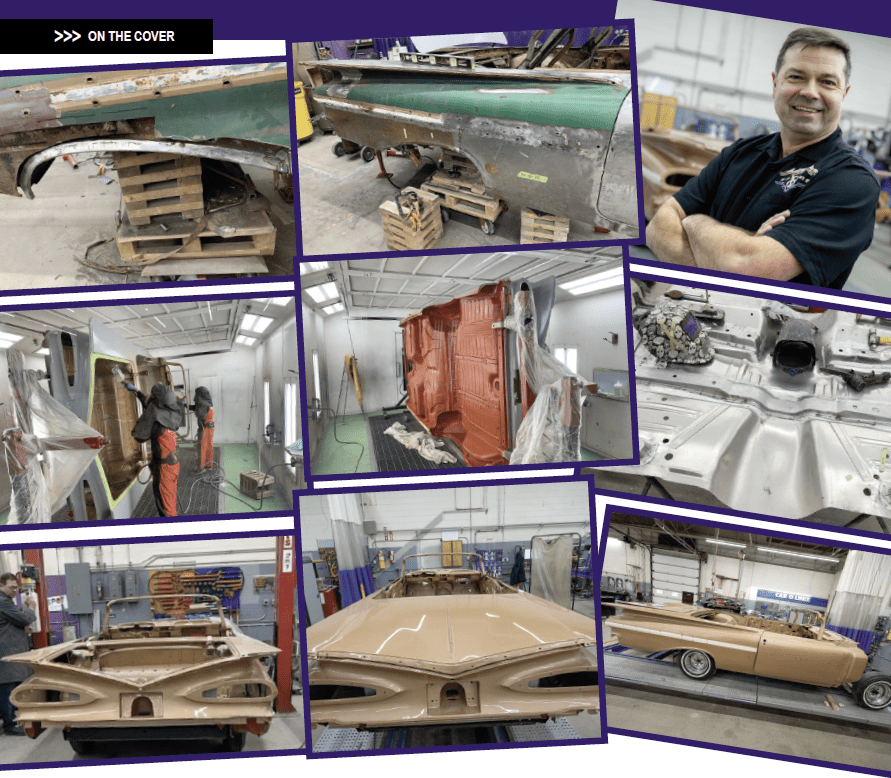

Kucharyshen further highlighted how auto body technician students tackled the repair and restoration project, which first began with understanding that, as with almost all vehicles, this 1959 Impala Convertible left the dealership shiny and new but fell into disrepair over time. That is, until the current owner discovered it, recognized its value and decided to restore it to its former glory. From here, Sask Polytech students worked on the body of the car. The owner dismantled it and delivered the body to the Saskatoon campus, where students replaced the floor, repaired the body and rotisserie-painted the car. Students performed a firewall, main floor and trunk floor replacement, complete with bracing. The quarter panels and wheelhouses were partially repaired and replaced, while the rest of the car, including the fenders, doors, hood and trunk, were either repaired, patched or replaced.

“Hands-on experiential learning is the most effective way for autobody students to learn. It directly connects theory to real-life scenarios.”

— Scott Kucharyshen, Saskatchewan Polytechnic Auto Body Program Head and instructor

And, when considering the value of the project, Kucharyshen was quick to outline how this project gave students the opportunity to be part of the overall experience.

“Hands-on experiential learning is the most effective way for autobody students to learn. It directly connects theory to real-life scenarios. As students progress through the program’s learning outcomes, they apply what they learn in the classroom to their hands-on assignments in the shop, ensuring each part of the car is completed correctly. If a task isn’t done properly, they must redo it to meet roadworthy standards.”

Moreover, just as the collision repair industry is a community dedicated to ensuring continued automotive safety, for Kucharyshen, so too is autobody work and education team based. “Autobody work requires each student to contribute to the projects’ overall progress. Students must work on their communication and teamwork skills throughout the program and to meet the project deadlines. Students are challenged at their individual skill levels, with advanced students tackling tougher assignments.”

With vehicles becoming more and more technologically advanced, Saskatchewan Polytechnic makes sure to balance the old and the new, so that students can be better prepared for all outcomes. Kucharyshen specifically stressed how special circumstances on vintage cars may arise, providing instructors with opportunities to teach beyond the standard curriculum, offering autobody students valuable extras. This approach builds class camaraderie that can last for years to come.

“Repairing vintage cars, like the 1959 Impala Convertible is a rewarding experience for both students and instructors. We receive many requests to work on and restore vintage cars. To be considered, each car must meet our Auto Body Technician certificate training requirements, have supplies and parts that we can either produce or purchase, and have the owner who can prepare the car in advance for student work. In the Auto Body Technician certificate program, we also work on late-model, low-mileage collision vehicles. Currently, we have three 2020 and newer collision-damaged vehicles in the shop.”

When asked about the value of restoration projects alongside potential technological training, Kucharyshen concluded that “working on vintage vehicles keeps our faculty excited about the training and connected with industry developments, including parts availability, tool advancements and repair procedures. When students are excited about their projects, so are we. I enjoy staying on campus after hours with students to help them paint and often spend my evenings researching and planning future projects while learning the history of a bygone era.

“It’s always exciting to see a vintage car restored by Sask Polytech students and reminiscing about our time working on the vehicle is a rewarding experience. It highlights the lasting impact of our hands-on learning experience.”

Ultimately, Kucharyshen is excited for both the future of the 1959 Impala Convertible and the restoration projects to come as students continue to build their skills.

“Once finished and assembled by the owner, we hope this car will be seen on the streets and at numerous car shows, providing students with a lasting memory of their time at Saskatchewan Polytechnic.”