SELF HEALING COATINGS CAN ALLOW VEHICLES TO HEAL THEIR OWN SCRAPES AND SCRATCHES

BY SARAH PERKINS

As the summer reaches its peak, the importance of protection from the sun’s sizzle becomes paramount—not just for our skin, but also for automotive coatings. Automotive coating protection acts like sunscreen for vehicles, safeguarding them from the harsh effects of sunlight, extreme temperatures and environmental contaminants. While paint protection fi lms (PPF) have existed since the mid 20th-century, recent advancements in automotive technology have propelled automotive SPF into the 21st-century in the form of self-healing automotive coatings.

As the summer reaches its peak, the importance of protection from the sun’s sizzle becomes paramount—not just for our skin, but also for automotive coatings. Automotive coating protection acts like sunscreen for vehicles, safeguarding them from the harsh effects of sunlight, extreme temperatures and environmental contaminants. While paint protection fi lms (PPF) have existed since the mid 20th-century, recent advancements in automotive technology have propelled automotive SPF into the 21st-century in the form of self-healing automotive coatings.

These coatings are said to not only protect a vehicle’s coating, but also possess the ability to repair minor scrapes and scratches on their own using advancements in materials science, nanotechnology and smart systems.

SELF-HEALING SETUPS

Self-healing automotive coatings primarily revolve around the development of smart materials and technology that can automatically repair damage. These materials are categorized into three main types.

POLYMERS

POLYMERS

Self-healing polymers are engineered to respond to damage through chemical reactions that restore their original state. Microcapsules fi lled with healing agents can be embedded in these polymers. When the material is damaged, these capsules break open, releasing the healing agent that fi lls the scratch or crack and solidifies, effectively repairing the damage.

METALS

METALS

Advances in metallurgy have led to the creation of self-healing metals that can mend themselves when exposed to heat or certain chemical reactions. These metals contain microvascular networks that transport healing agents to damaged areas, similar to how blood vessels in the human body function. However, given the general immobility of metal atoms, this option has proven more diffi cult to achieve than other methods.

COATINGS

COATINGS

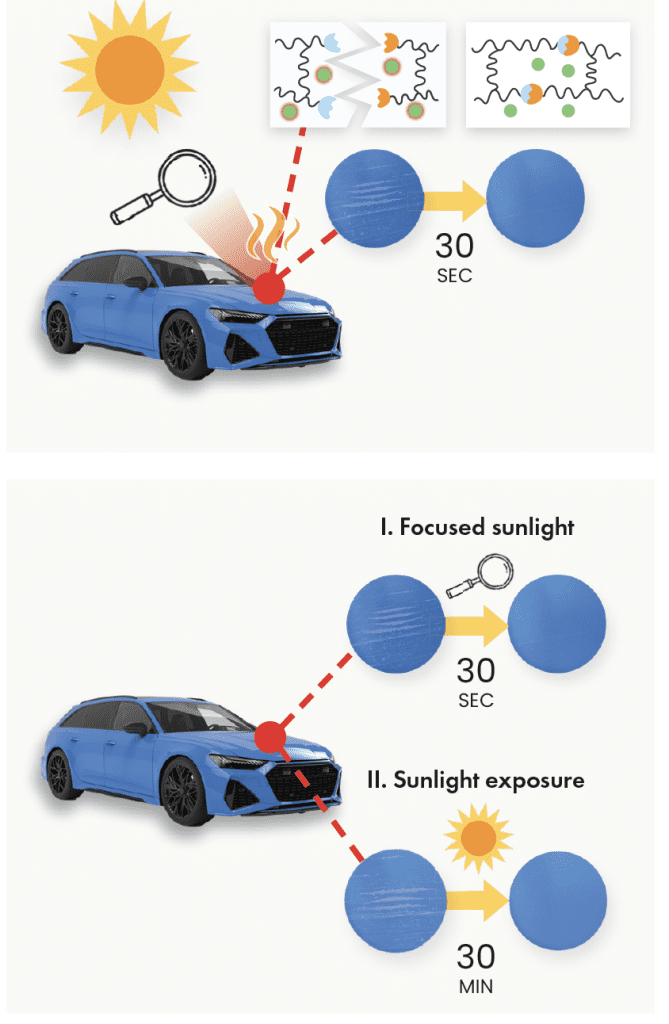

Self-healing coatings are applied to the surfaces of a car to protect against scratches and minor dents. These coatings can similarly contain capsules with a healing agent or possess intrinsic self-healing properties that activate under specific conditions, such as exposure to sunlight or heat.

There are two main self-healing coating types. The fi rst and most common option is a clear coat layer that is applied over a vehicle’s colour coat as a liquid by the vehicle manufacturer. Comparatively, a thin plastic sheeting such as a paint protective fi lm works more like a vehicle wrap and can be applied over existing vehicle paint. In both instances, these coatings have the chemical properties that allow internal molecular structures to rearrange themselves to an original state.

While self-healing coatings may be an ongoing technological development, the technology in its current state offers many potential applications for the automotive industry in the form of material protection, repair time savings and vehicle longevity.

COST

COST

The development and production of self-healing materials can be expensive. Reducing costs through research and large-scale production is needed for widespread adoption.

DURABILITY

DURABILITY

Ensuring that self-healing materials can withstand harsh automotive environments over the long term is crucial. Continuous testing and refinement are necessary to meet industry standards.

INTEGRATION

INTEGRATION

Integrating self-healing materials with existing automotive manufacturing processes requires significant changes in current automotive design and production techniques.

EARLY APPLICATIONS: 1970S TO 2000S

While the concept and application of self-healing coatings may be a more recent development, the idea of paint protection film was originally developed in the mid 20th-century with military applications in mind in order to protect helicopter blades from debris. In the 1980s, this protective concept was then adopted by NASCAR professionals who began applying the material to the nose cones of vehicles to better protect advertising decals. From here, the technology then transitioned more broadly throughout the automotive industry.

The idea of self-healing materials dates to the late 20th-century with early research primarily focused on polymers and composites. The goal was to create manufacturing materials that could repair themselves much like a biological system. In the early 2000s, self-healing coatings began to gain traction with researchers exploring options such as reversible polymers and microencapsulation—a process involving embedding tiny capsules filled with healing agents within the coating. When the capsules are damaged, these capsules break open, releasing the healing agents to fill the cracks and restore the surface.

The early 2000s also marked the beginning of significant interest in self-healing coatings within the automotive industry. Early prototypes used microencapsulation technology, but these initial attempts faced challenges, including limited durability and effectiveness under varying environmental conditions.

MODERNIZED METHODS: 2000S TO 2010S

The mid-2000s to 2010s saw the development of reversible polymers which allowed automotive coatings to heal repeatedly. Another notable breakthrough at this time was the use of supramolecular chemistry which relies on non-covalent interactions to enable self-healing. As a result, these coatings could heal at a molecular level.

Some automotive manufacturers that began offering vehicles with self-healing paint during this period included Nissan with the 2009 Infiniti G37, which received a clear coat called Scratch Shield—a technology that today is also used to help protect cell phones.

FUTURE APPLICATIONS: 2020S AND BEYOND

Present developments in automotive self-healing coatings include the introduction of ultraviolet-curable coatings as well as heat-responsive polymers that allow for faster and more efficient healing processes.

While self-healing automotive coatings can’t repair severe damage to a vehicle’s chassis, they are perhaps one solution for future dents and scratches. In order to continue being developed for future automotive manufacturing, continued education, training and research is needed so that the technology can overcome current challenges.

Currently, specific training courses and certifications for self-healing coatings in the automotive industry are not as widely available, established or recognized as those for PPF. However, professionals working with self-healing coatings can benefit from certain related certifications and training programs that focus on advanced coating technologies and surface protection. For PPF training in general, organizations such as XPEL, 3M and Suntek offer a variety of courses teaching industry members on effective methods to apply PPF to vehicles.

POLYMERS

POLYMERS METALS

METALS COST

COST DURABILITY

DURABILITY