RIGHT FIT

Both Bentley Motors and Ford made 3D-printing announcements to kick off the year, with the former announcing its exploration in 3D printed vehicle components, down to powertrains, and the latter releasing open-source files for customized interior accessories. Bentley’s announcement came alongside an investment in the automaker’s additive manufacturing (AM) capacity at its Crewe, England, factory, where all its models are assembled. The AM unit has been tasked to create physical components for several prototype Bentleys, down to full-scale powertrain and aerodynamic wind tunnel models. Ford, on the other hand, has opened a treasure trove of personalization options alongside the release of open-source CAD files for customers to 3D print accessories for the Maverick pickup truck. The files are for the Maverick’s Ford Integrated Tether Systems (FITS), a series of slots at the rear of the centre console and the under-seat storage bins that allow for customization with a wide variety of accessories, from dog water bowls to (likely non-functional) mini-Yeti coolers.

Bentley’s recent investment in its additive manufacturing facility (pictured), where all its models are assembled.

WHY NOT BOTH

PPG has found North Americans cannot seem to make up their minds on just one colour and have developed an affinity for twotone finishes, as shown the company’s 2021 automotive colour popularity report. PPG’s press release issued alongside the report suggests that progression in the fields of colour science and application technology has given way to an increased desire for colour personalization among consumers. “Along with special-order colours, tinted clearcoats, tri-coats and matte finishes, two-tone finishes better reflect vehicle owners’ individual preferences and personalities,” said PPG colour styling manager Misty Yeomans. The company says it has developed a method for achieving a two-tone finish that eliminates labour-intensive body masking and repeated runs through the spray booth that have historically prevented the trend from taking off on a mass-production scale. “PPG’s precision application process can reduce paint shop application time by approximately 50 minutes per two-tone vehicle,” the company claims in its press release.

NIGHT MOVES

The IIHS has announced that it is putting in the work to develop testing to address one of the most glaring downfalls of modern vehicle safety—nighttime AEB functionality. New research from the Insurance Institute for Highway Safety has shown that AEB systems are often ineffective in low-light situations, such as on roads without streetlights. A preliminary nighttime test was conducted with eight vehicles, none of which performed adequately according to IIHS standards. Current IIHS data shows that vehicles equipped with AEB systems are in crashes 27 percent less frequently and have an injury reduction rate of 30 percent. “This is the first real-world study of pedestrian AEB to cover a broad range of manufacturers, and it proves the technology is eliminating crashes,” said Jessica Cicchino, IIHS vice president of research and the study’s author. “Unfortunately, it also shows these systems are much less effective in the dark, where three-quarters of fatal pedestrian crashes happen.”

APP AWARENESS

Onboard vehicle technologies come together with new vehicle purchases nowadays, but that doesn’t necessarily mean vehicles are becoming safer, advocates say. “This is a major and an increasing issue,” said Ian Jack, head of public affairs at the Canadian Automobile Association. “It’s becoming increasingly challenging for people to manage these things inside their vehicle.” CAA’s campaign comes as distracted driving, which includes tasks such as eating, talking with passengers and using vehicle technology, has been a rising contributor to fatal and serious collisions. The Traffic Injury Research Foundation show that as of 2018, distracted driving contributes to one in four fatal crashes. Canada introduced guidelines in 2019 for limiting distractions from displays, but they’re not enforceable. Transport Canada spokeswoman Sau Sau Liu said in a statement that the agency “encourages vehicle and electronics manufacturers to design devices that are compatible with safe driving and to follow all relevant safety guidelines and best practices.” She said Transport Canada would continue to update guidelines as the technology evolves.

KEEPING IT LIGHT

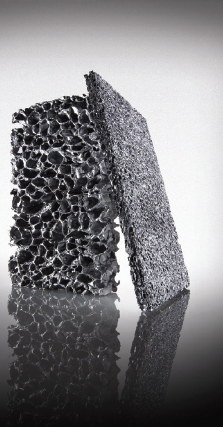

The Automotive Parts Manufacturers Association’s (APMA) Project Arrow will feature crash system components from Canadian manufacturer Cymat Technologies and its design partner Tesseract Structural Innovations. Cymat and Tesseract will design and supply several components for specific areas of the Project Arrow concept car, including Cymat’s SmartMetal aluminum foam, which the company says combines ultra-lightweight features with high-strength aluminum skins. The companies said Project Arrow’s doors, battery enclosures and front and rear crash systems could incorporate the SmartMetal tech. “The challenge in building the vehicle of the future is to balance active technology with a lightweight philosophy,” said APMA president Flavio Volpe. “To win the range game, Automakers need a transformational materials science strategy. This is Project Arrow’s bet on Cymat.”

Project Arrow’s all Canadian concept will incorporate Mississauga, Ontario-based Cymat’s SmartMetal aluminum foam, which the company says features ultra-lightweight features with high-strength aluminum skins.